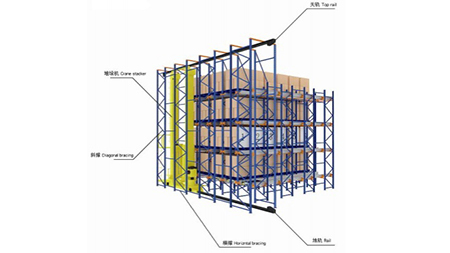

Merlins asrs manufactures the most robust rail running automated storage and retrieval system using a rotating fork front end that can access all industry standard pallet racking.

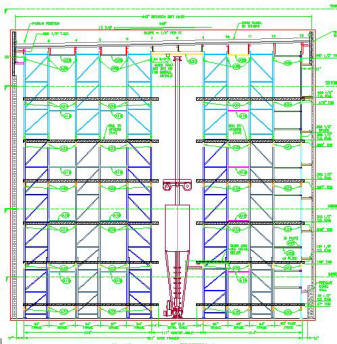

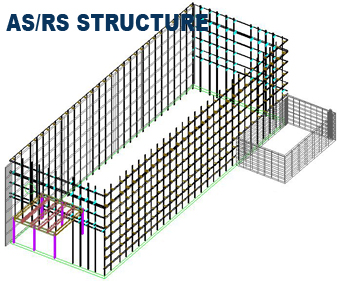

The automated storage and retrieval systems asrs can be found in the layout.

Delivery time is the most important aspect in your warehouse these days.

The systems operate under computerized control maintaining an inventory of stored items.

Unit load asrs 2.

The system has a central lift which stacks material onto racks on both the sides.

Automated item retrieval system 9.

Automated storage and retrieval systems as rs were once considered out of reach by many smaller order fulfillment operations and retail warehouses who did not have the budget to invest in such advanced technology.

Vts 08 is a tower type storage system developed with our understanding of the requirements of modern stores.

They can also be programmed to match layouts cut off times shipping zones or however else you would need your asrs system to organize.

Kardex remstar is a leading supplier of automated storage and retrieval solutions that maximize efficiency for your system.

No longer are designers and users constrained with low performance high operating cost fork truck systems.

As rs systems are designed for automated storage and retrieval of parts and items in manufacturing distribution retail wholesale and institutions.

Some of the important categories include.

The automated storage and retrieval horizontal carousel system increases productivity and reduces labor by up to 2 3 by brining items to the operator and eliminating wasted walking searching activities.

Type of as rs several types of asrs are distinguished based on certain features and applications.

These complex functions can be eased and better control can be had on overall stores functions and security by installing and automated system.

Horizontal carousel can be used manually as rotating shelving or integrated as semi automated and fully automated system.

Calculate the true cost of storage space reduced labor requirements asrs systems require 2 3 less labor to operate when compared to manual shelving.

Compact footprint asrs technologies provide highly dense storage and can save up to 85 of floor space occupied by shelving.

But as as rs technology has rapidly advanced over the years new options provide a wide variety of size speed cost and flexibility and has caused the rate of system adoption.

With a huge array of products and solutions kardex remstar can meet your requirements for automated storage and retrieval systems asrs that are both application and industry specific.

They first originated in the 1960s initially focusing on heavy pallet loads but with the evolution of the technology the handled loads have become smaller.

With asrs systems you can have items placed at the bottom of pallets or the asrs can organize them to make like items go together.