But if we use dc supply from a rectifier then the dc will be pulsating dc and hence it induces emf in the core and causes eddy currents to flow.

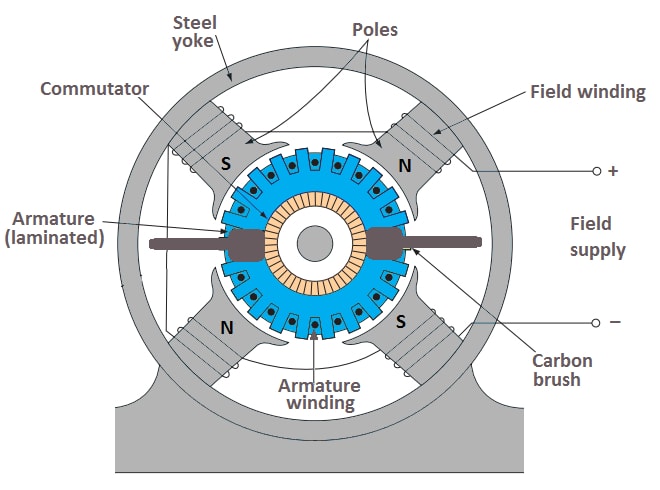

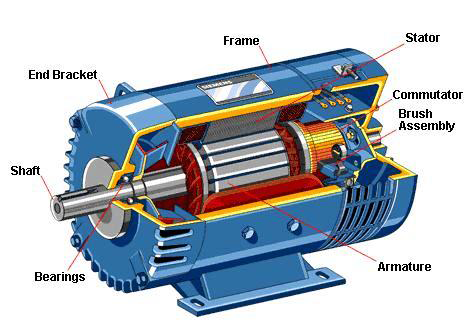

The armature of a dc motor is laminated.

Note thinner the laminations greater is the resistance offered to induced e m f.

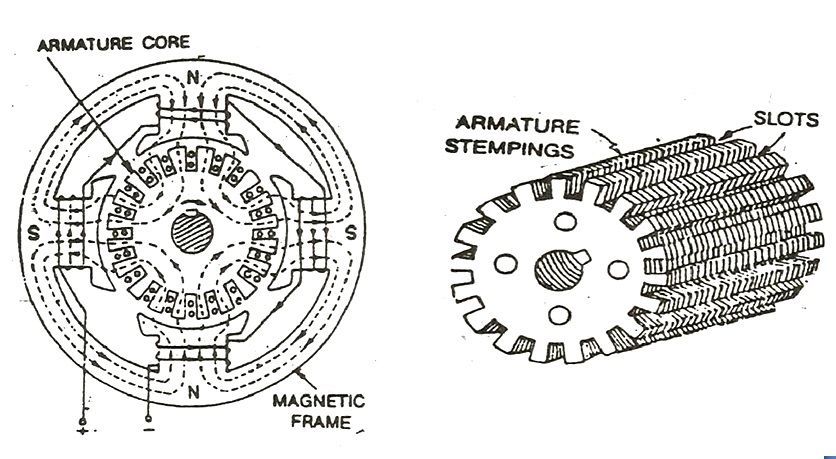

Motor laminations are created by using electrical steel laminations.

That is why armature of dc machines either motor or generator is laminated.

So lamination of the core is done only when your power electronic converter feed the field excitation to the dc machine.

Similarly armature core is laminated to reduce eddy current losses.

Shunt generators each with armature resistance of 0 02 ohm and field resistance of 50 ohm run in parallel and supply a total current of 1000 amperes to the load circuit.

Therefore smaller the current hence lesser eddy current loss.

Motor armatures have to be made of thin laminations of iron to work efficiently a plain solid iron armature would waste a lot of energy in at least two ways the magnetic field that is produced by.

Adding silicon to steel increases its electrical resistance improves the ability of magnetic fields to penetrate it and reduces the steel s hysteresis loss.

Are 270 v and 265 v their bus bar voltage will be.

The sum of the eddy currents in the laminated core is smaller than the current in the solid core.

Silicon steel also known as electrical steel is steel with silicon added to it.

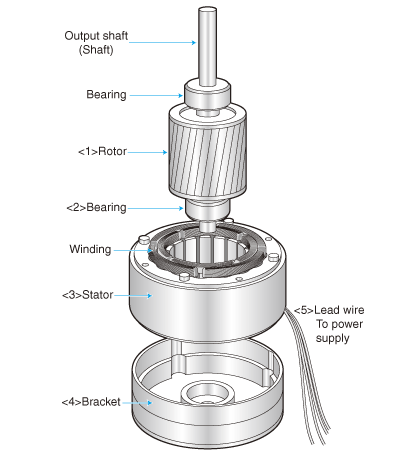

For this reason the rotor is made of armature core that s made with several low hysteresis silicon steel lamination to reduce the magnetic losses like hysteresis and.

Reduce hysterisis loss.

The armature of dc machine is made up of laminated sheets to.

The top image depicts a solid armature while the bottom image shows an armature made of five laminations.

The armature winding of dc motor is attached to the rotor or the rotating part of the machine and as a result is subjected to altering magnetic field in the path of its rotation which directly results in magnetic losses.

By reversing the connections of either the armature or the field winding connection with the supply.